2021-09-28

A hidden champion of gearing technology

RINGSPANN’s expanding sleeve mandrel is increasing flexibility in fine machining

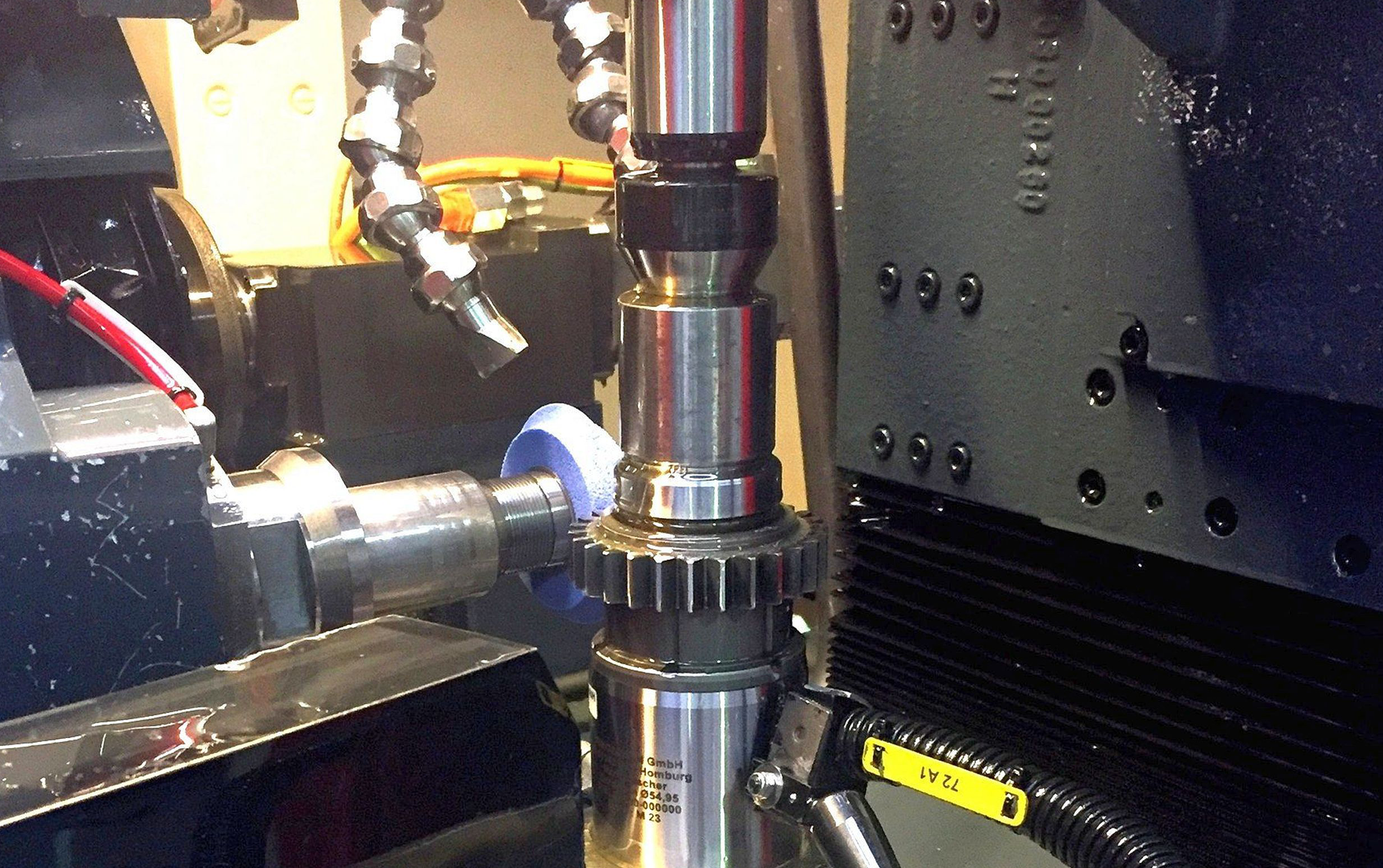

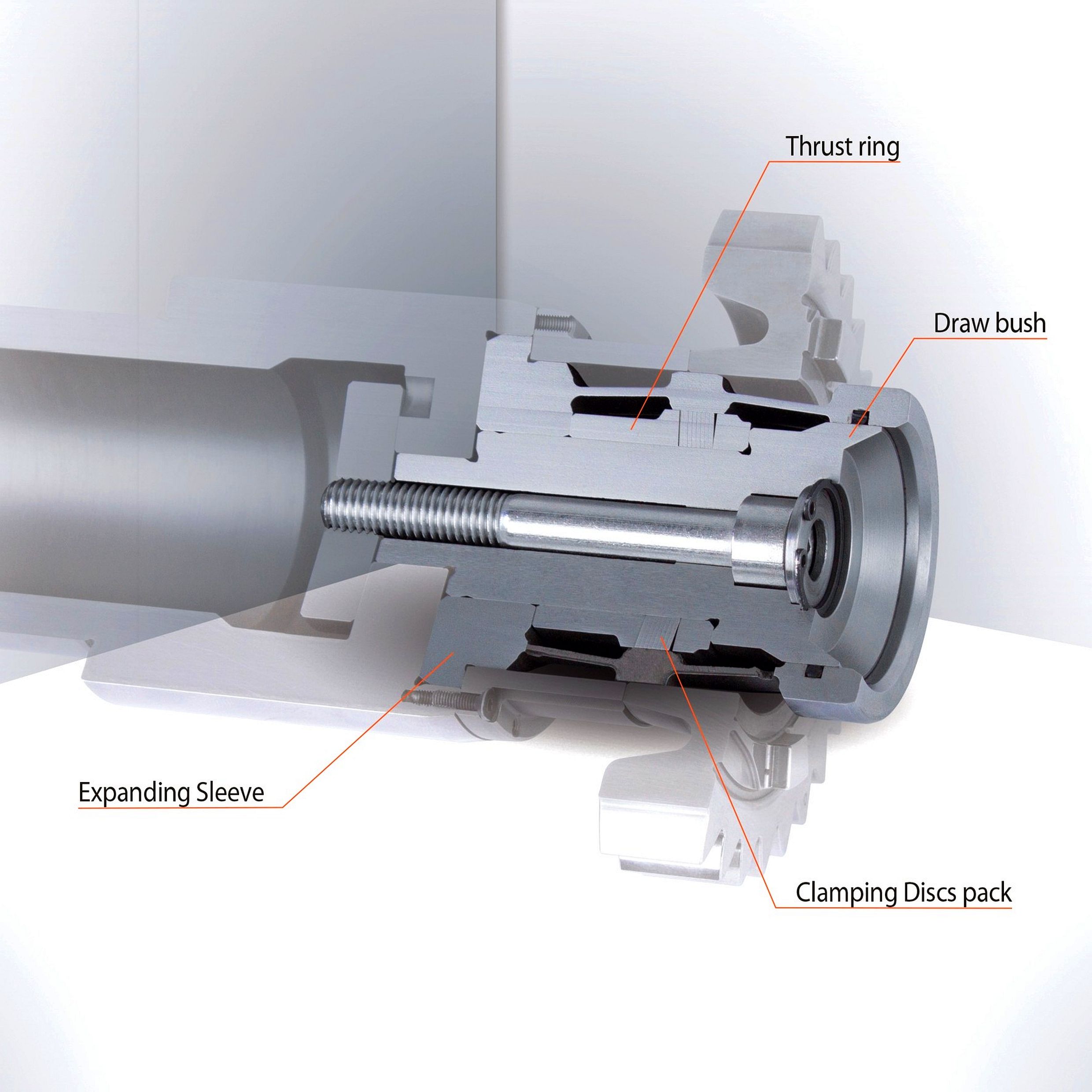

For all manufacturers of gear cutting machines and users in the field of fine machining who have particularly high demands on the precision and flexibility of their clamping fixtures, RINGSPANN has a real hidden champion in its range: the mechanical expanding sleeve mandrel HDDS. As an alternative to hydraulic expanding fixtures, it convinces with a comparably high concentricity of ≤ 5 µm with a surprisingly great expansion. While the first manufacturers are testing the patented HDDS as a potential standard component in their gear cutting machines, RINGSPANN is also positioning it as a component for simplified entry into automated production.

Bad Homburg, September 2021. – The mechanical production of high-quality spur and bevel gears for use in gear manufacturing in particular has been characterised for years by increasing demands on their geometric accuracy. For a long time, customers in this sector of fine machining were satisfied with gear qualities of 8 or 9 according to DIN 3961, but today suppliers are usually required to achieve qualities of level 7 or 6. And if you want to survive as a supplier in motor racing, gear qualities of at least 5 or 4 are the gold standard. Yet every experienced gear manufacturer knows that such high accuracies cannot be achieved without specially designed clamping fixtures. Volker Schlautmann, head of RINGSPANN’s clamping fixtures/ shaft-hub-connections customer team, puts it in a nutshell: "Ideally, such a clamping system not only supports gear technicians in meeting the constantly increasing quality requirements, but also provides them with more application and economic flexibility." It was this threefold objective that guided Volker Schlautmann’s team in the development of the HDDS expanding sleeve mandrel.

Clamping without risk of leakage

As a mechanical internal clamping system, the HDDS is a real highlight of modern clamping technology. It convinces with a concentricity of ≤ 5 µm, offers an absolute expansion four times greater than that of most hydraulic clamping fixtures, and is therefore currently regarded as one of the best mechanical alternatives to the hydraulic expanding mandrels often found in gearing technology. "Our HDDS accommodates workpieces with bores up to tolerance class IT10, while most hydraulic clamping fixtures are only suitable for accommodating workpiece bores up to tolerance class IT7," specifies Volker Schlautmann. Since the expanding sleeve mandrel from RINGSPANN, unlike hydraulic expanding clamping fixtures, is also free of any leakage risks, its use increases process reliability in series production, where even the smallest leakage on hydraulic clamping fixtures triggers the need for repair. The only source of wear on RINGSPANN’s HDDS is its clamping discs. "But they are quality products with long service lives from our own production, which are also easy to replace," stresses Volker Schlautmann.

Higher accuracies than expected

The HDDS from RINGSPANN was able to demonstrate its performance capability and power reserves during high-precision cylindrical gear grinding in the production of a Swiss gear manufacturer. Here, its axial and radial run-out accuracy were measured both with a control workpiece on a tactile measuring device and with an original blank in a coordinate measuring system. The results were even better than expected: The measuring equipment recorded accuracies of ≤ 2 µm for the axial runout and ≤ 3 µm for the radial runout. "In addition, the geometric accuracy achieved for the involute toothing on the series workpiece was well within the defined tolerance limits and thus well above the customer’s requirements," notes Volker Schlautmann.

High flexibility due to large expansion

Other practical cases have since shown that the expanding sleeve mandrel from RINGSPANN not only enables the achievement of high gearing qualities, but that it also supports the realisation of fully automated manufacturing concepts. The reason for this is easy to understand: Since hydraulic expanding mandrels have only a low expansion rate due to their physics, high-precision handling systems are usually needed to feed them, which also drives up the costs for the required measurement and control technology for the periphery. As already mentioned, the HDDS from RINGSPANN, on the other hand, has an expansion that is four times greater than that of many hydraulic clamping fixtures. "Due to the high expansion rate, the technical expenditure for the entire periphery is considerably reduced, which makes the entry into fully automated machining much easier," emphasises Volker Schlautmann.

RINGSPANN’s mechanical expanding sleeve mandrel is capable - depending on the version - of clamping bores with diameters from 25 mm and is also suitable for bores whose internal geometry is interrupted by a groove. In addition, it can also be used to machine components with very short clamping lengths, because its mechanics provide a pull-back action in which the workpiece is pressed against a contact and aligned at the same time. Also worth mentioning: In applications in high-precision machining, it has been shown that further advantages can be achieved by using a spindle sleeve because this increases the reproducibility of the clamping result to ≤ 2 µm - while simultaneously increasing the rigidity of the entire system. "This also means that the clamping system is insensitive to very large radial forces applied by the tools," explains Volker Schlautmann. ms

Delivery in just two weeks

RINGSPANN can deliver the standard series HDDS mechanical expansion sleeve mandrel within just two weeks. To simplify the design work, 3D CAD models of the HDDS are also available for free download on the company’s website.